THE MAKING

Pringle of Scotland use the finest Cashmere, from goats bred mainly in the mountain areas of China and Tibet. It is our policy to procure only the finest white fibre, which allows us to produce a wide range of colours which not only look and feel beautiful but are robust enough to wear regularly.

White fibre is the most expensive, as it can only be obtained from the chest and underbelly of the goat and there is a limited amount available from this area.

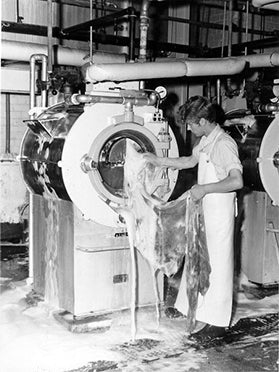

The process of ‘milling’ (washing) is a hugely important part of cashmere production. It’s also probably the most scientific; a combination of using very soft water and specific softening agents. This process is important for removing any impurities, e.g. natural grease and oil. How much water, detergent, polymer and time required for milling is calculated according to the pantone colour chosen, in order to ensure the fibre opens. Only after the fibre has opened will the garment achieve the right level of tension and the luxurious and iconic cashmere feel.

Millers have developed the unique Pringle of Scotland cashmere handle over many decades working with our teams to perfect the process. We require specific degrees of twist and percentage of oil in our yarns and we specify the exact tension that we want our cashmere knitted to.